count inventory with barcode scanner

Counting inventory is an essential task for businesses across various industries, including the catering industry.To streamline this process and ensure accuracy, many professionals are turning to barcode scanners.

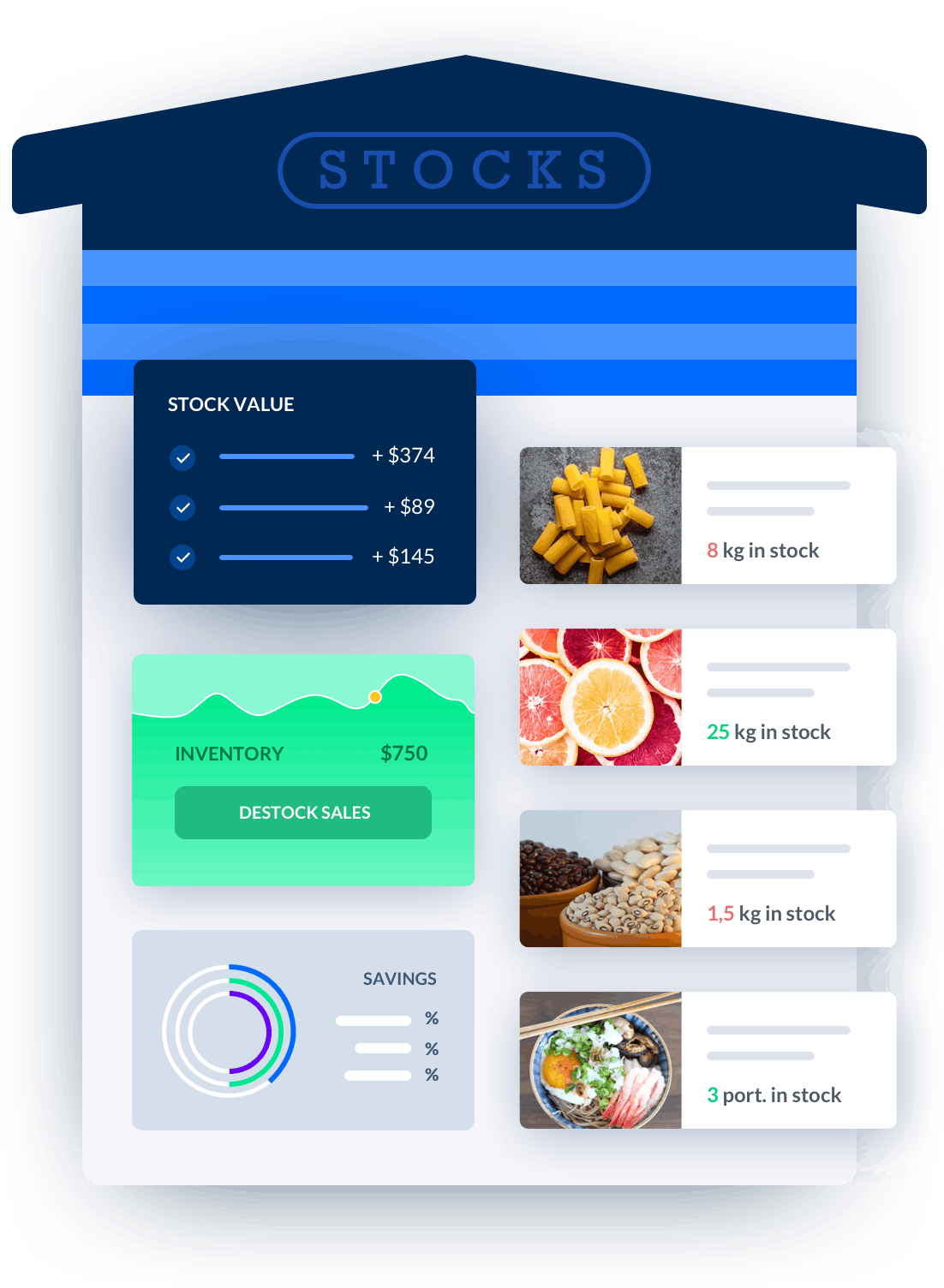

Melba: inventory management software

Discover how to optimize your inventory management with melba

Inventory management in catering, increase your cash flow

Good inventory management in food service helps to avoid waste, ensure that demand can be met, and avoid tying up cash. Find out how to optimize your inventory in this article!

Counting inventory is an essential task for businesses across various industries, including the catering industry. To streamline this process and ensure accuracy, many professionals are turning to barcode scanners. Barcode scanners offer a simple and efficient way to count inventory, eliminating manual errors and saving valuable time. In this article, we will explore the benefits of using barcode scanners for inventory counting and provide some useful tips for implementing this technology effectively.

The Advantages of Using Barcode Scanners for Inventory Counting

Barcode scanners provide several advantages when it comes to counting inventory. Let's take a closer look at these benefits:

1. Increased Efficiency

Using barcode scanners significantly speeds up the inventory counting process. With a simple scan, the scanner captures the barcode information, eliminating the need for manual data entry. This automation saves time and allows professionals to focus on other essential tasks.

2. Improved Accuracy

Manual inventory counting is prone to human errors, such as miscounts or incorrect data entry. Barcode scanners eliminate these errors by capturing accurate information directly from the barcode. This ensures that your inventory records are reliable and up-to-date.

3. Enhanced Inventory Management

Barcode scanners integrate seamlessly with inventory management systems, providing real-time updates on stock levels. This integration allows professionals to track inventory movements, monitor stock availability, and make informed purchasing decisions. It also facilitates efficient stock replenishment and minimizes the risk of overstocking or stockouts.

Tips for Implementing Barcode Scanners for Inventory Counting

Now that we understand the benefits of using barcode scanners for inventory counting, let's explore some practical tips for implementing this technology:

1. Choose the Right Barcode Scanner

There are various types of barcode scanners available, including handheld scanners and fixed-mount scanners. Consider your specific needs and environment when selecting a scanner. Ensure that it is compatible with your inventory management system and supports the type of barcodes used in your industry.

2. Barcode Labeling

Proper barcode labeling is crucial for accurate scanning. Ensure that each item in your inventory is labeled with a unique barcode that is easy to scan. Additionally, regularly inspect and replace damaged or faded barcode labels to maintain scanning efficiency.

3. Train Your Staff

It is essential to provide training to your staff on how to use barcode scanners effectively. Familiarize them with the scanning process, including proper positioning and scanning techniques. This training will ensure consistent and accurate scanning across your inventory management team.

Common Challenges and Solutions

While using barcode scanners for inventory counting offers numerous benefits, it is essential to be aware of potential challenges. Here are some common challenges and their corresponding solutions:

1. Barcode Damage

Barcodes can become damaged or unreadable due to wear and tear. Regularly inspect and replace damaged barcodes to ensure accurate scanning. Implementing barcode verification processes can help identify and rectify barcode issues before they affect inventory counting.

2. Connectivity and Compatibility

Ensure that your barcode scanner is compatible with your inventory management system. Check for connectivity options such as Bluetooth or USB, depending on your requirements. Additionally, periodically update your scanner's firmware to maintain compatibility with evolving technologies.

3. Environmental Factors

Environmental factors, such as poor lighting or dusty conditions, can affect barcode scanning accuracy. Ensure that your scanning environment is well-lit and free from debris. Consider using barcode scanners with built-in lighting or laser technologies designed to handle challenging environments.

Conclusion

By incorporating barcode scanners into your inventory counting process, you can significantly improve efficiency and accuracy. These scanners streamline the inventory management process, providing real-time updates and minimizing manual errors. Remember to choose the right scanner, properly label your items, and train your staff to maximize the benefits of this technology. Overcoming common challenges will ensure smooth implementation and enhance your inventory management practices. Embrace barcode scanners to take your inventory counting to the next level!