food stock control procedures

Food stock control procedures are crucial for any business in the catering industry to ensure efficient management of inventory and prevent wastage.By implementing effective stock control procedures, businesses can optimize their operations, reduce costs, and enhance customer satisfaction.

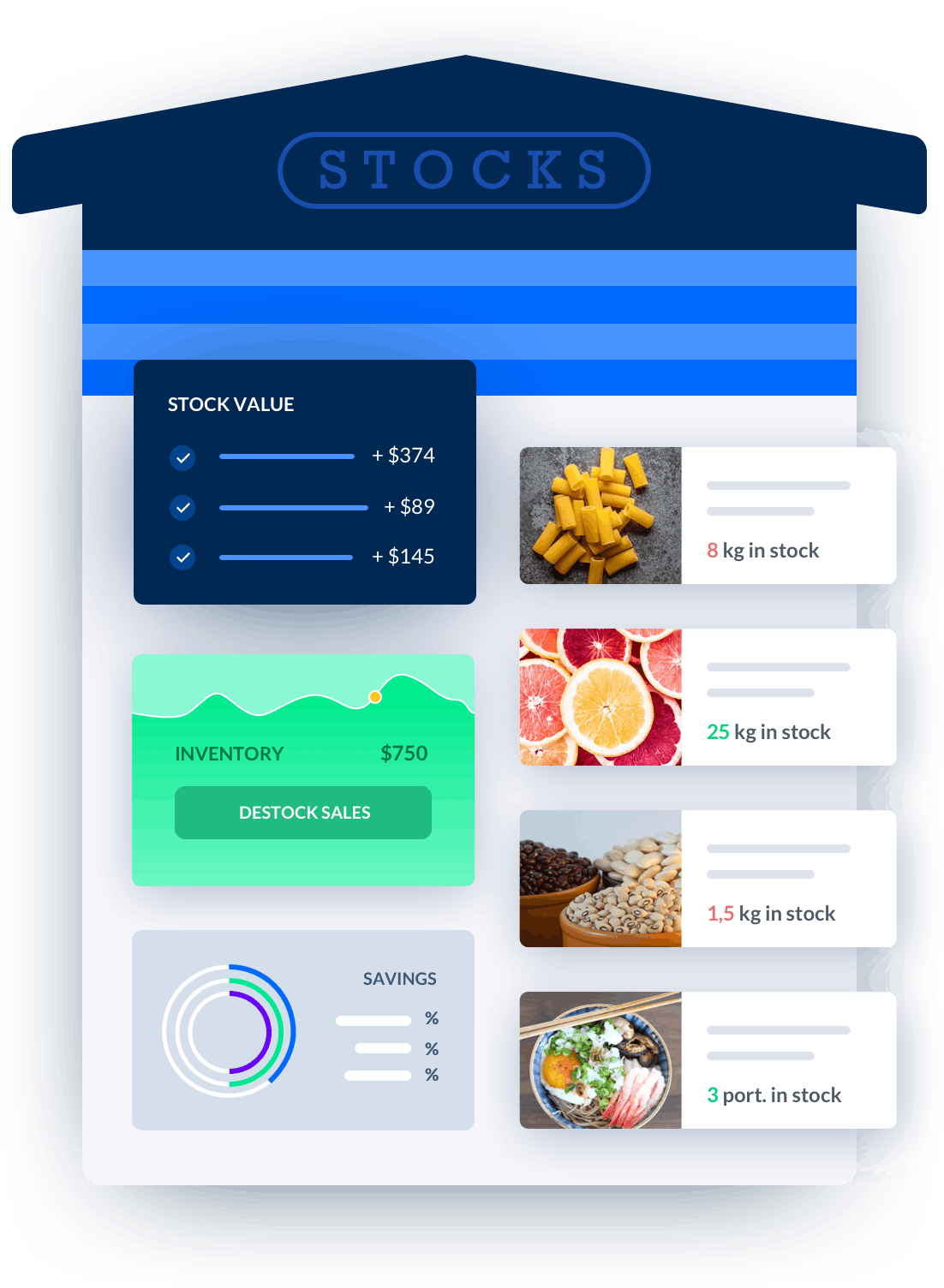

Melba: inventory management software

Discover how to optimize your inventory management with melba

Inventory management in catering, increase your cash flow

Good inventory management in food service helps to avoid waste, ensure that demand can be met, and avoid tying up cash. Find out how to optimize your inventory in this article!

Food stock control procedures are crucial for any business in the catering industry to ensure efficient management of inventory and prevent wastage. By implementing effective stock control procedures, businesses can optimize their operations, reduce costs, and enhance customer satisfaction. In this article, we will explore key strategies and best practices for food stock control.

1. Importance of Food Stock Control

Efficient stock control is essential for the smooth functioning of any catering business. By maintaining accurate inventory records and implementing effective procedures, businesses can:

- Minimize food wastage and spoilage

- Prevent overstocking or understocking

- Ensure timely reordering of supplies

- Optimize cash flow and reduce carrying costs

- Enhance customer satisfaction through consistent availability of menu items

1.1 Accurate Inventory Management

Accurate inventory management lies at the foundation of effective stock control. It involves:

- Regularly updating inventory records

- Conducting physical stock counts

- Using inventory management software to track stock levels

- Implementing a first-in, first-out (FIFO) approach to minimize food waste

1.2 Forecasting and Demand Analysis

Forecasting future demand is crucial for determining stock requirements. By analyzing historical data, market trends, and seasonal variations, businesses can accurately predict demand and adjust stock levels accordingly.

- Use sales data and customer feedback to identify popular menu items

- Monitor market trends and seasonal fluctuations

- Collaborate with suppliers to optimize stock levels

2. Effective Food Stock Control Procedures

Implementing the following procedures can help businesses maintain effective control over their food stock:

2.1 Categorize and Organize Stock

Proper categorization and organization of stock streamline inventory management processes. Consider grouping items based on their nature, such as perishable, non-perishable, or high-demand items. Additionally, ensure clear labeling and adequate storage conditions to prevent confusion and spoilage.

2.2 Set Par Levels and Reorder Points

Establishing par levels and reorder points helps maintain optimal stock levels. Par levels represent the minimum quantity of each item required to meet demand until the next order arrives. Reorder points indicate when to initiate the replenishment process.

- Regularly review and adjust par levels based on demand fluctuations

- Monitor stock levels to ensure timely reordering

- Consider lead time when setting reorder points

2.3 Use Technology for Efficient Tracking

Leveraging technology can significantly enhance stock control procedures. Inventory management systems, barcode scanners, and point-of-sale (POS) software can automate data entry, track stock movement, and generate real-time reports.

- Implement an inventory management system tailored to your business needs

- Utilize barcode scanners for accurate stock tracking

- Integrate POS software with inventory management for seamless stock control

3. Monitoring and Analysis

Continuous monitoring and analysis of stock control procedures allow businesses to identify areas for improvement and make informed decisions. Consider the following practices:

3.1 Regular Stock Audits

Conducting regular stock audits helps identify discrepancies between recorded and actual stock levels. By reconciling inventory records with physical counts, businesses can identify theft, spoilage, or inaccuracies in stock management.

- Perform surprise audits to discourage theft

- Train staff on accurate stock counting techniques

- Investigate discrepancies and take necessary corrective measures

3.2 Analyze Stock Turnover Ratio

The stock turnover ratio measures how quickly inventory is sold and replenished. By calculating this ratio, businesses can assess the efficiency of their stock control procedures and identify slow-moving items or excessive stock levels.

- Regularly calculate stock turnover ratio

- Identify slow-moving items and adjust stock levels accordingly

- Optimize purchasing decisions based on demand patterns

3.3 Supplier Management

Establishing strong relationships with suppliers is crucial for efficient stock control. Maintaining open communication, negotiating favorable terms, and ensuring timely deliveries can help prevent stockouts and streamline the procurement process.

- Regularly evaluate supplier performance

- Communicate stock requirements and lead times effectively

- Consider alternative suppliers for diversification and better pricing

In conclusion, effective food stock control procedures are essential for the success of catering businesses. By implementing accurate inventory management, forecasting demand, and following best practices, businesses can optimize their stock control processes, minimize wastage, and enhance customer satisfaction. Utilizing technology, regularly monitoring stock, and analyzing key metrics further contribute to efficient stock control. Remember, efficient stock control is a continuous process that requires ongoing evaluation and adjustment to meet changing market demands.